Businesses should schedule timely stretch wrap machine repair to avoid unwanted downtime.

Businesses should schedule timely stretch wrap machine repair to avoid unwanted downtime.

Blog Article

Recognizing the Value of Timely Stretch Wrap Maker Fixing Solutions

When it concerns extend cover devices, prompt repair work can make all the distinction. You know that even minor mechanical or electrical concerns can lead to unforeseen downtime, affecting your assembly line. Dealing with these troubles quickly not just protects performance yet likewise improves the top quality of your covered items. So, what factors should you consider to guarantee your devices stay in top shape? Allow's explore this important element even more.

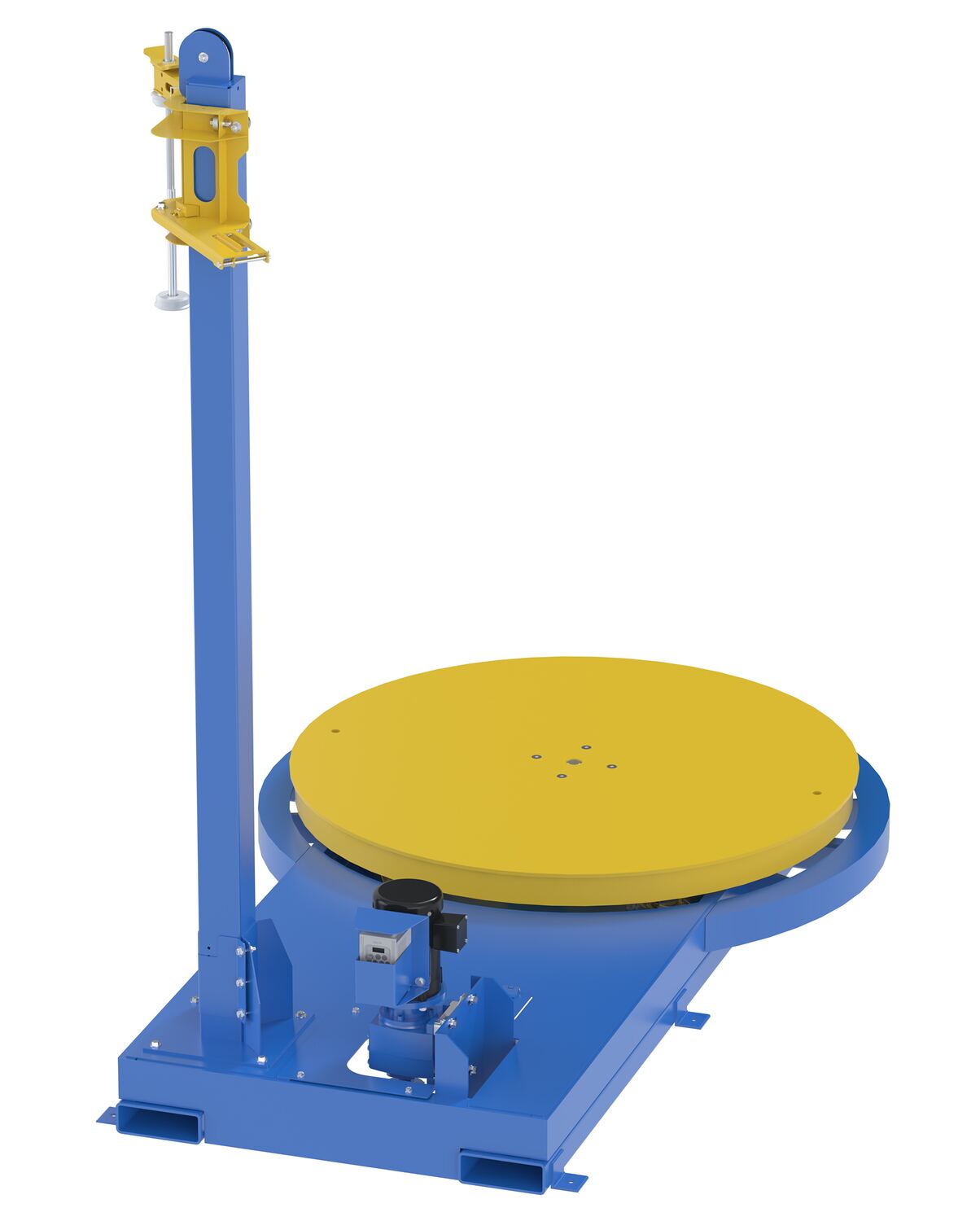

The Duty of Stretch Cover Machines in Modern Manufacturing

Stretch cover equipments play an important role in modern production by making sure that products are securely packaged for transportation and storage. You depend on these equipments to offer stability and defense, preventing damages throughout transit. When you make use of stretch cover, you reduce the threat of products changing or obtaining smashed, which can cause costly losses.

In addition, utilizing stretch cover equipments can enhance your overall supply chain effectiveness. By simplifying the packaging procedure, you decrease labor prices and speed up shipment times, ensuring that your clients obtain their items promptly. In today's hectic market, this benefit is essential.

Common Concerns That Lead to Maker Downtime

When your stretch cover machine experiences downtime, it can commonly be mapped back to mechanical failures or operator errors. Recognizing these typical issues can help you prevent pricey disruptions. By attending to these factors, you can maintain your operations running smoothly.

Mechanical Failures and Break Downs

Mechanical failings and breakdowns can significantly disrupt your operations, causing pricey downtime. These concerns often stem from worn-out parts, such as equipments and belts, or not enough lubrication. When parts use down or break, your stretch wrap device may halt unexpectedly, impacting performance. Additionally, electrical failures can trigger malfunctions in the device's control system, producing further hold-ups. Routine maintenance is important to catch these problems early and maintain your devices running smoothly - stretch wrap machine repair. Overlooking minor issues can bring about bigger, much more expensive fixings down the line. By focusing on timely fixings, you're not just decreasing downtime yet additionally prolonging the lifespan of your equipment. Remain proactive, and keep your procedures efficient and nonstop.

Operator Errors and Oversights

While operators play a crucial duty in the smooth functioning of your stretch wrap device, their mistakes and oversights can lead to substantial downtime. Common problems like incorrect loading, wrong settings, and failing to monitor wrap stress can create delays and product damages. If an operator disregards to examine for damaged film, it can lead to inconsistent wrapping and boosted waste. In addition, miscommunication during shifts can lead to crucial modifications being forgotten. It is essential to supply thorough training and regular refreshers to lessen these mistakes. Motivating a society of liability and vigilance among your team can considerably lower downtime. Ultimately, investing in operator training pays off by enhancing efficiency and extending your maker's life expectancy.

The Financial Effect of Delayed Repair Work

Delaying fixings on your stretch wrap machine can lead to significant economic repercussions that ripple via your entire procedure. When your device breaks down, efficiency plummets.

Additionally, extended hold-ups can escalate minor problems right into significant problems, requiring a lot more considerable repair work or also full replacement of the machine. Eventually, prompt repairs are necessary to preserving your bottom line and making certain smooth operations.

Advantages of Proactive Maintenance Programs

Timely repair services can save you from pricey downtime, yet carrying click here to find out more out a proactive upkeep program takes it an action better. By frequently arranging maintenance, you can determine prospective problems prior to they intensify into significant problems. This not only keeps your stretch cover machine running efficiently yet likewise extends its life expectancy. You'll discover that consistent upkeep minimizes the chance of unanticipated malfunctions, enabling your operations to run more efficiently.

Furthermore, a proactive method enhances performance. With fewer disturbances, your workforce can concentrate on their tasks without the stress and anxiety of unexpected device failings. Plus, you'll likely conserve on repair work expenses, as small concerns are generally less costly to repair than considerable repair work. Maintaining peak performance can enhance the quality of your wrapped items, ensuring client contentment. In the lengthy run, a positive upkeep program is a financial investment that pays off with increased dependability and price savings.

Recognizing Indicators That Your Machine Demands Repair

As you operate your stretch wrap device, it is important to stay cautious for signs that indicate it may need repair work. Among the initial things to seek is unusual noise. If you hear grinding, squeaking, or any type of other strange sounds, it might indicate a hidden concern. Additionally, watch for inconsistent wrapping. If the movie isn't stuck properly or you notice unequal stress, your equipment may be malfunctioning.

Another indication is an increase in downtime. If your maker regularly stops or calls for modifications, it is time to examine. Likewise, watch on the machine's rate; if it's slower than normal, something might be wrong. Any kind of noticeable damage like torn cable televisions or leaks should not be overlooked. Promptly attending to these indications can protect against a lot more significant issues down the line, ensuring your procedures run smoothly.

Picking the Right Repair Work Solution for Your Needs

Just how do you choose the ideal fixing solution for your stretch wrap maker? Look for professionals who specialize in stretch wrap devices and have a tried and tested track document.

Following, evaluate their response time. A trusted service ought to provide timely assistance, as equipment downtime can be pricey. It's also vital to know if they offer emergency repairs.

Don't fail to remember to ask concerning warranties on repairs and components. A respectable solution backs visit this page up their job, offering you assurance.

Finally, contrast prices however avoid picking solely based on price. Occasionally, the cheapest option might bring about poor service. By taking into consideration these variables, you'll locate a repair work service that meets your needs and keeps your stretch cover device running smoothly.

Techniques for Minimizing Stretch Cover Maker Downtime

Educating your drivers is an additional vital approach. Furnish them with the expertise to identify and attend to small glitches before they cause significant break downs. Urge them to keep a log of any type of abnormalities, which aids in detecting problems much faster.

Additionally, maintaining a supply of necessary extra parts can dramatically reduce downtime. When something breaks, having the best parts accessible implies you won't have to wait on deliveries.

Finally, consider purchasing real-time monitoring systems. These systems can alert you to efficiency adjustments, enabling for prompt treatment. By executing these strategies, you'll maintain your stretch wrap device running smoothly and efficiently.

Regularly Asked Concerns

How Commonly Should Stretch Wrap Machines Be Serviced?

You must service stretch cover equipments consistently, ideally every six months. If you discover any kind of efficiency concerns or uncommon noises, do not wait-- schedule maintenance promptly to stop expensive break downs and guarantee peak effectiveness.

What Are the Common Costs Related To Stretch Wrap Equipment Repairs?

Typical costs for stretch cover device repairs differ, yet you could anticipate to spend between $200 to $1,500 relying on the concern. Regular maintenance can aid decrease these prices and prolong your device's lifespan.

Can I Do Basic Maintenance on My Stretch Wrap Equipment?

Yes, you can execute fundamental upkeep on your stretch cover maker. Consistently inspect for wear and tear, clean the elements, and guarantee proper lubrication. Keeping it healthy can extend its lifespan and enhance effectiveness.

How Do I Know if a Fixing Service Is Reliable?

To locate a reliable repair work solution, examine on the internet reviews, request for referrals, and verify certifications. A dependable solution will offer clear estimates, guarantee alternatives, and prompt interaction, guaranteeing you really feel positive in their proficiency.

What Should I Perform in Situation of an Emergency Machine Break Down?

In case of an emergency machine break down, you ought to immediately quit operations, examine the concern, and call your repair solution. Keep vital contact numbers convenient, and record the problem for reliable troubleshooting when assistance arrives.

Final thought

To summarize, recognizing the significance of timely stretch cover maker repair work can greatly enhance your procedures. By addressing problems promptly, you reduce downtime and prevent pricey failures. Accepting aggressive upkeep not only prolongs your tools's lifespan yet likewise improves efficiency and customer contentment. Remember to remain alert for signs of wear and choose a reputable fixing service to keep your devices running efficiently. Buying these services repays in the long run, ensuring your supply chain stays effective and efficient.

Report this page